APPROACHES TO ROOT CAUSE ANALYSIS

APPROACHES TO ROOT CAUSE ANALYSIS

There are many methodologies, approaches, and techniques for conducting root cause analysis, including:

- Events and causal factor analysis: Widely used for major, single-event problems, such as a refinery explosion, this process uses evidence gathered quickly and methodically to establish a timeline for the activities leading up to the accident. Once the timeline has been established, the causal and contributing factors can be identified.

- Change analysis: This approach is applicable to situations where a system’s performance has shifted significantly. It explores changes made in people, equipment, information, and more that may have contributed to the change in performance.

- Barrier analysis: This technique focuses on what controls are in place in the process to either prevent or detect a problem, and which might have failed.

- Management oversight and risk tree analysis: One aspect of this approach is the use of a tree diagram to look at what occurred and why it might have occurred.

- Kepner-Tregoe Problem Solving and Decision Making: This model provides four distinct phases for resolving problems:

- Situation analysis

- Problem analysis

- Solution analysis

- Potential problem analysis

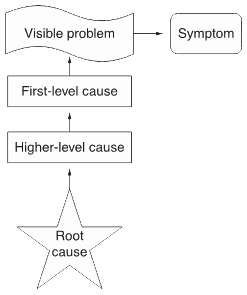

Root Cause Analysis Diagram

CONDUCTING ROOT CAUSE ANALYSIS

When carrying out root cause analysis methods and processes, it’s important to note:

- While many root cause analysis tools can be used by a single person, the outcome generally is better when a group of people work together to find the problem causes.

- Those ultimately responsible for removing the identified root cause(s) should be prominent members of the analysis team that sets out to uncover them.

A typical design of a root cause analysis in an organization might follow these steps:

- A decision is made to form a small team to conduct the root cause analysis.

- Team members are selected from the business process/area of the organization that experiences the problem. The team might be supplemented by:

- A line manager with decision authority to implement solutions

- An internal customer from the process with problems

- A quality improvement expert in the case where the other team members have little experience with this kind of work

- The analysis lasts about two months. During the analysis, equal emphasis is placed on defining and understanding the problem, brainstorming its possible causes, analyzing causes and effects, and devising a solution to the problem.

- During the analysis period, the team meets at least weekly, sometimes two or three times a week. The meetings are always kept short, at maximum two hours, and since they are meant to be creative in nature, the agenda is quite loose.

- One person in the team is assigned the role of making sure the analysis progresses, or tasks are assigned to various members of the team.

- Once the solution has been designed and the decision to implement has been taken, it can take anywhere from a day to several months before the change is complete, depending on what is involved in the implementation process.